ALUMASTER High Speed Disc

Certainly more stock removal

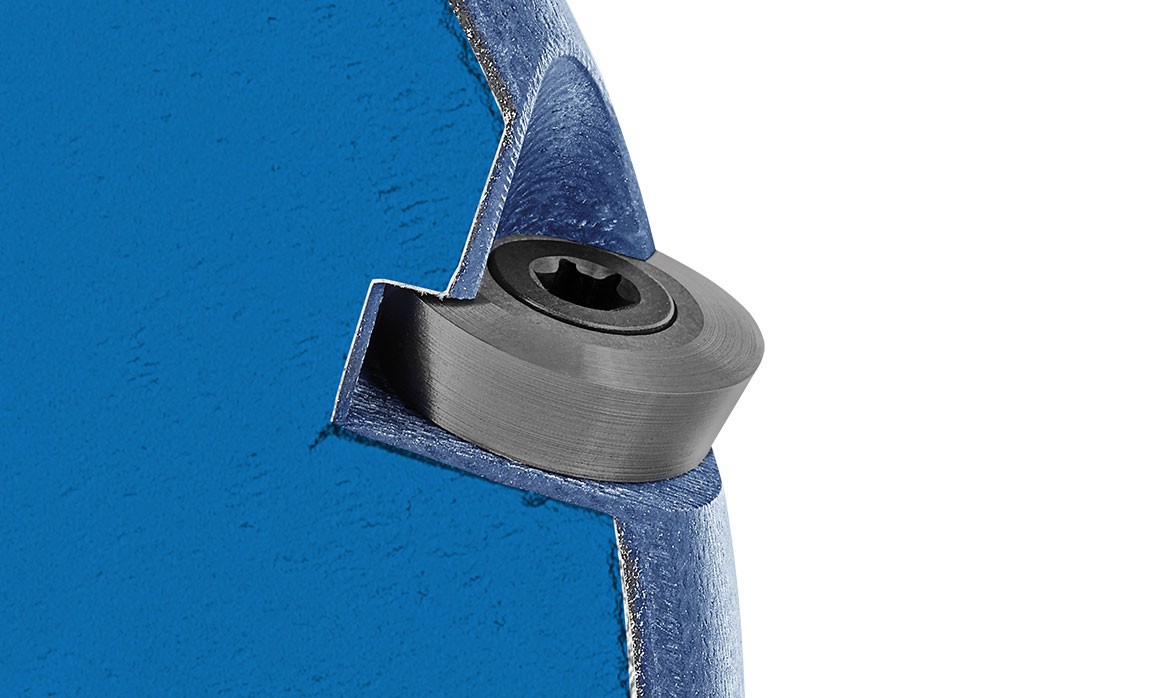

The innovative ALUMASTER High Speed Disc is a unique tool with an extremely high stock removal rate. It is ideal for processing aluminium as it does not generate hazardous or explosive dust. It consists of specially developed tungsten carbide cutting inserts, which are fixed to the High Speed Disc.

Different versions

The HSD-F 115/125 version is suitable for surface work . The HSD-R 115/125 version has taken the HSD-F one step further. The HSD-R version can be used for surface work as well as radially for milling out root seams or for peripheral milling . The compact HSD-R 50 version enables delicate and hard-to-reach components to be effectively machined.

Advantages:

- Does not generate hazardous or explosive dust.

- An extraction system is not required.

- Cost-effective and eco-friendly alternative to grinding wheels and flap discs of comparable weight.

-

Innovative and robust geometry:

- the highest degree of safety,

- extreme durability and

- comfortable work.

- Specially developed, turnable and replaceable tungsten carbide cutting inserts.

- Exceptionally high stock removal rate.

Materials:

- Aluminium alloys

- Brass, copper, zinc

- Bronze

- Plastics

- Fibre-reinforced thermosetting plastics (GRP, CRP)

Industries:

- Shipbuilding and yacht construction

- Rail car construction

- Silo and container construction

- Vehicle construction

Recommendations for use:

The tool has primarily been designed for use on aluminium, wrought aluminium alloys and cast aluminium. Non-ferrous metals with a relatively low strength and fibre-reinforced plastics can also be machined. This must be checked for the specific application on a case-by-case basis.

ALUMASTER with HICOAT coating

PFERD also offers the cutting inserts with a premium-quality HICOAT coating for lubricating cast aluminium alloys with a silicon content of 5–10%, abrasive cast aluminium alloys with a silicon content of over 15%, and for other abrasive materials or non-ferrous metals. This prevents tool clogging and abrasive wear, even in use on these particularly demanding materials.

Additional advantages of the HICOAT coating:

- Extremely hard

- Very low friction coefficient

- Very low tendency towards adhesion

- Improved surface quality

- Reduced burr formation

Materials for which the HICOAT coating is recommended:

- Lubricating cast aluminium alloys with 5–10% silicon content

- Sticky, greasy materials

- Abrasive cast aluminium alloys with a silicon content > 15%

- Abrasive materials such as fibre-reinforced plastics (FVK)

- Non-ferrous alloys of higher strength than aluminium (bronze, brass, etc.)

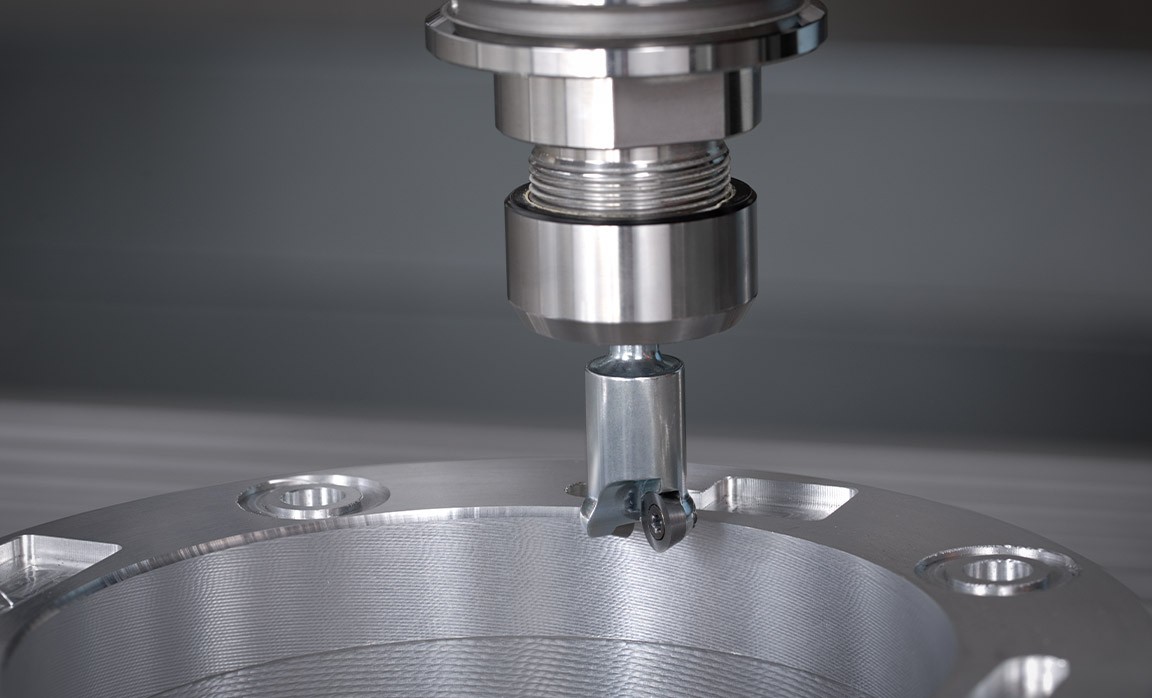

High Speed Torus Cutter

The High Speed Torus Cutter is an unparalleled tool for use on robots with an extremely high stock removal rate. Thanks to its compact design, the High Speed Torus Cutter is the ideal tool for working in hard-to-reach areas and on delicate points such as grooves, pockets and tight radii and contours.

The Cutter perfectly complements the ALUMASTER High Speed Disc in the HSD-R 50 version and burrs with the ALU cut.