Milling tools with ALUMASTER HICOAT cutting inserts, HSD-R design for radial applications

High-performance milling disc ALUMASTER R dia. 115 mm for angle grinders work on aluminium HICOAT

HSD-R 115/125 ALUMASTER HICOAT

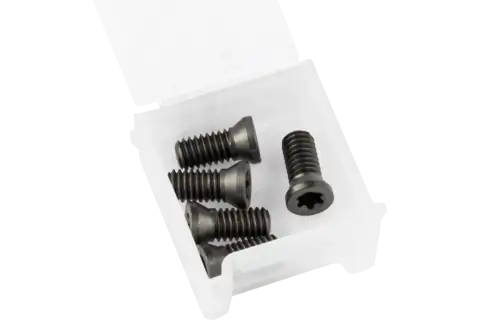

Matching accessories & spare parts

Technical information

High-performance milling disc ALUMASTER R dia. 115 mm for angle grinders work on aluminium HICOAT

- Dia. external

- 115 mm

- Dia. hole

- 22.23 mm

- RPM, soft non-ferrous metals

- 13300 RPM

- RPM, thermoplastics, reinforced (GRP/CRP) with a fibre content of less than 40%

- 13000 RPM

- Width

- 8 mm

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

Safety notes

Contents

- Materials that can be worked

- Applications

- Drive types

PFERD TOOLS VALUE

PFERD TOOLS EFFICIENCY

recommends the ALUMASTER HICOAT High Speed Discs for working for long periods with low levels of fatigue, whilst saving resources and achieving perfect results as quickly as possible.

PFERD TOOLS ERGONOMICS

recommends the ALUMASTER HICOAT High Speed Discs as an innovative tool solution for work on aluminium as they do not generate hazardous or explosive dust.