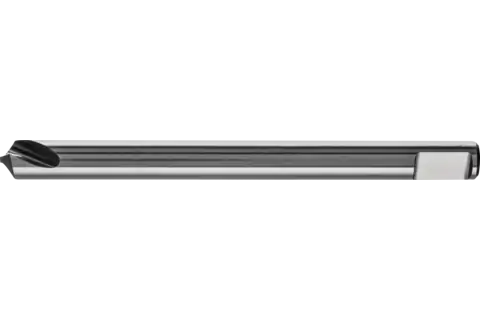

TC hole cutter deep version 60 mm, shank dia. 12 mm

Tungsten carbide hole cutter/hole saw dia. 60x60 mm shank dia. 12 mm cutting depth 57 mm universal

LOS HM 6060

Matching accessories & spare parts

Technical information

Tungsten carbide hole cutter/hole saw dia. 60x60 mm shank dia. 12 mm cutting depth 57 mm universal

- Dia. external

- 60 mm

- Dia. shank

- 12 mm

- RPM, rust and acid-resistant steels

- 105 - 265 RPM

- RPM, soft non-ferrous metals

- 230 - 350 RPM

- RPM, steels up to 1,200 N/mm²

- 210 - 320 RPM

- RPM, thermoplastics, reinforced (GRP/CRP) with a fibre content of less than 40%

- 230 - 350 RPM

- Packaging unit

- 1 piece

Description

Special features

Recommendations for use

Ordering notes

- Materials that can be worked

- Applications

- Drive types