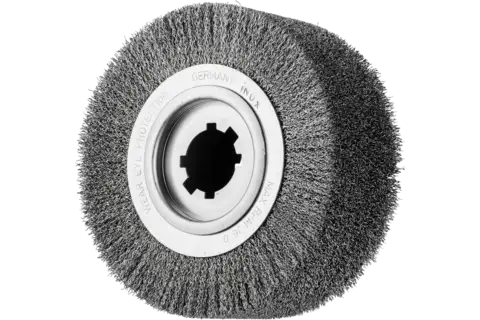

Wheel brushes crimped deburring brushes, with hole

Deburring brush crimped RBU dia. 250x100x50.8 mm hole stainless steel wire dia. 0.50 mm stationary

Technical information

Deburring brush crimped RBU dia. 250x100x50.8 mm hole stainless steel wire dia. 0.50 mm stationary

- Dia. external

- 250 mm

- Dia. filament material

- 0.5 mm

- Dia. hole

- 50.8 mm

- Dia. hole, max.

- 100 mm

- Filament material

- Stainless steel wire (INOX)

- Length, filament

- 50 mm

- Max. RPM

- 3600 RPM

- Mounting system

- Centre hole

- RPM, optimum, from

- 1400 RPM

- RPM, optimum, to

- 2300 RPM

- Width

- 100 mm

- Packaging unit

- 1 piece

Description

Advantages

Recommendations for use

Ordering notes

- Materials that can be worked

- Applications

- Drive types