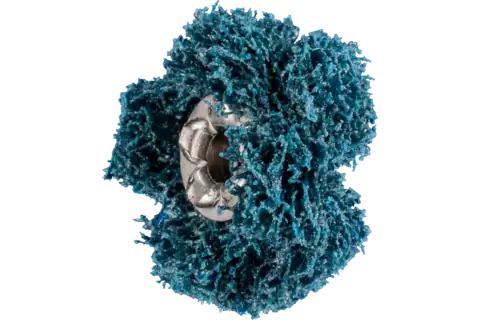

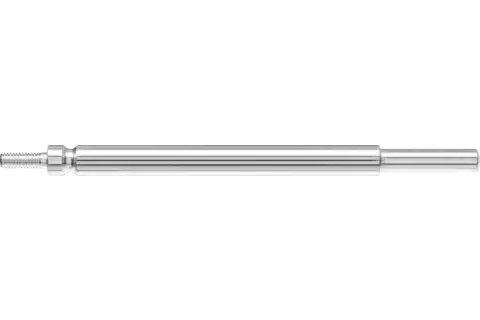

POLINOX cross buffs PNST

POLINOX non-woven cross buff PNST dia. 19 mm thread 8-32 UNC A100 for fine grinding and finishing

PNST 19-2 A 100

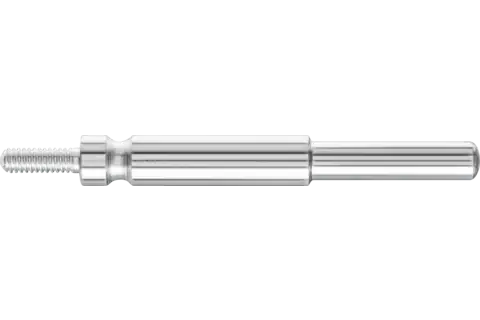

Matching accessories & spare parts

Technical information

POLINOX non-woven cross buff PNST dia. 19 mm thread 8-32 UNC A100 for fine grinding and finishing

- Abrasive

- Aluminium oxide A

- Dia. external

- 19 mm

- Grit size

- 100

- Max. RPM

- 25100 RPM

- Number, layers

- 2 pcs.

- RPM, optimum

- 15000 RPM

- Packaging unit

- 20 pieces

Description

Special features

Recommendations for use

Ordering notes

Safety notes

- Materials that can be worked

- Applications

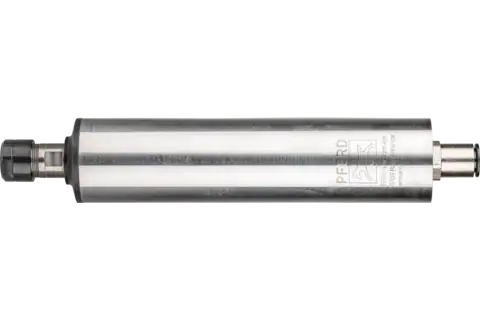

- Drive types

PFERD TOOLS VALUE

PFERD TOOLS ERGONOMICS

recommends POLINOX cross buffs to sustainably reduce the vibration and noise produced during use and to improve comfort when working.