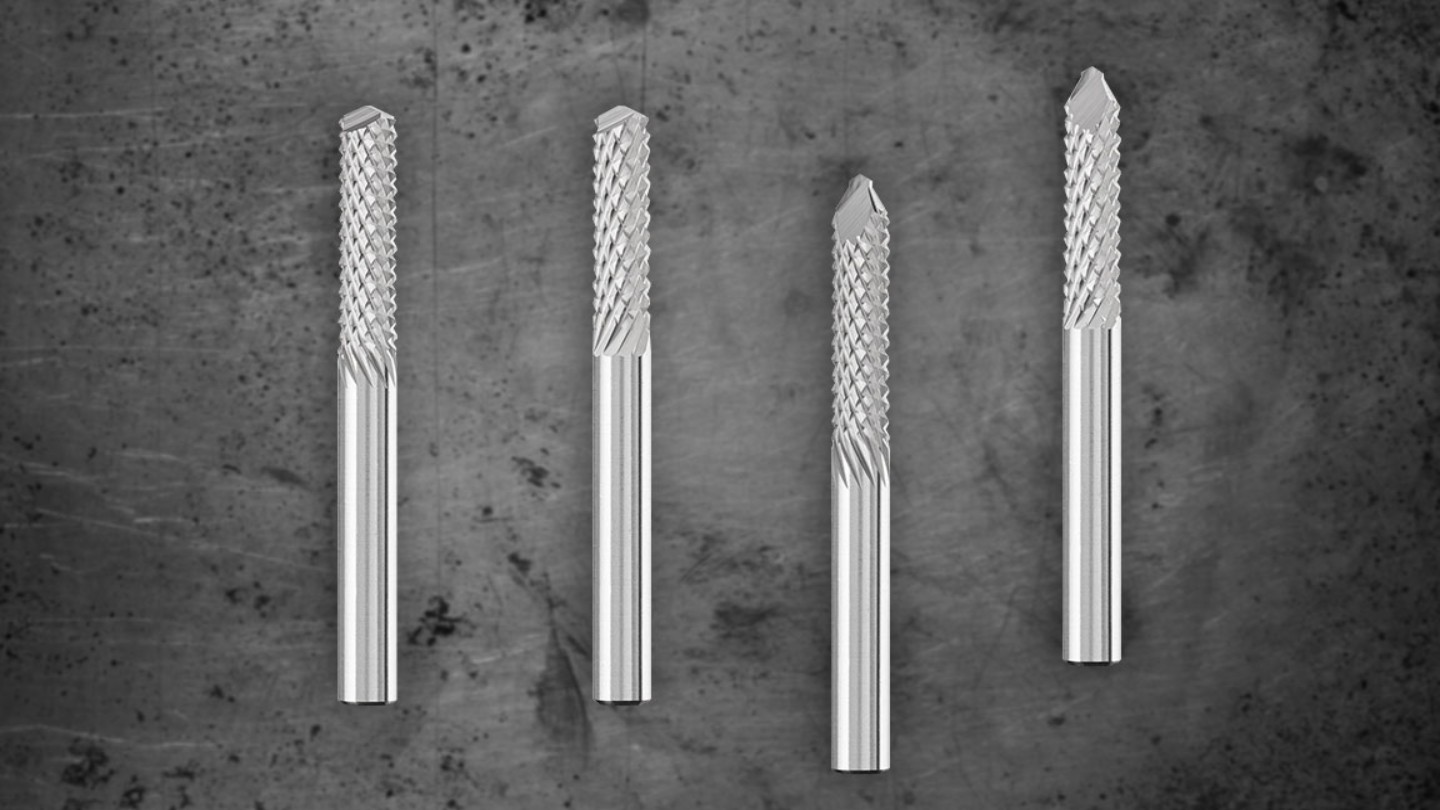

TC burrs - FVK/FVKS cut

Tungsten carbide burrs with the FVK and FVKS cuts are suitable for universal use on hard glass and carbon-fibre-reinforced duroplastics. Due to its high concentricity, the FVK cut is suitable for tool machines and manual applications. It is characterized by smooth milling and produces a smooth cut edge.

The FVKS cut is suitable for use on machines and robots with high feed rates.

Advantages:

- Particularly suitable for GRP and CRP, also with > 40 % fibre content.

- The FVKS cut produces smooth edges and is characterized by smooth milling.

- Reduced wear on the tool drive due to impact-free work without chatter marks, thanks to the high concentricity.

Materials that can be worked:

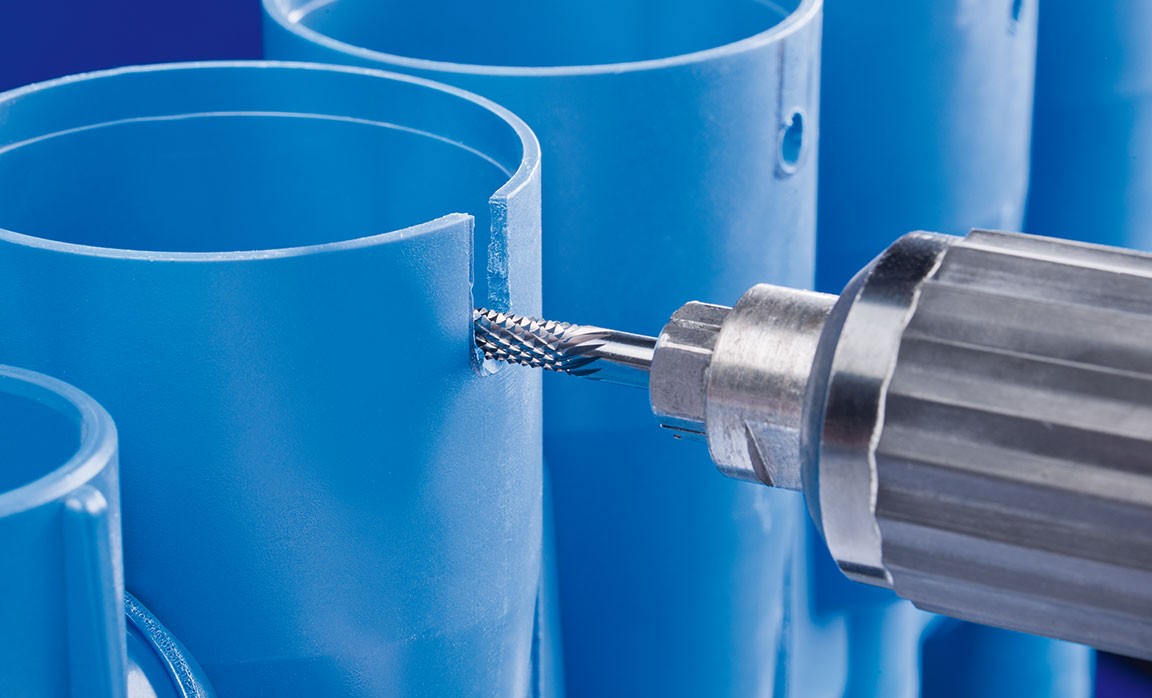

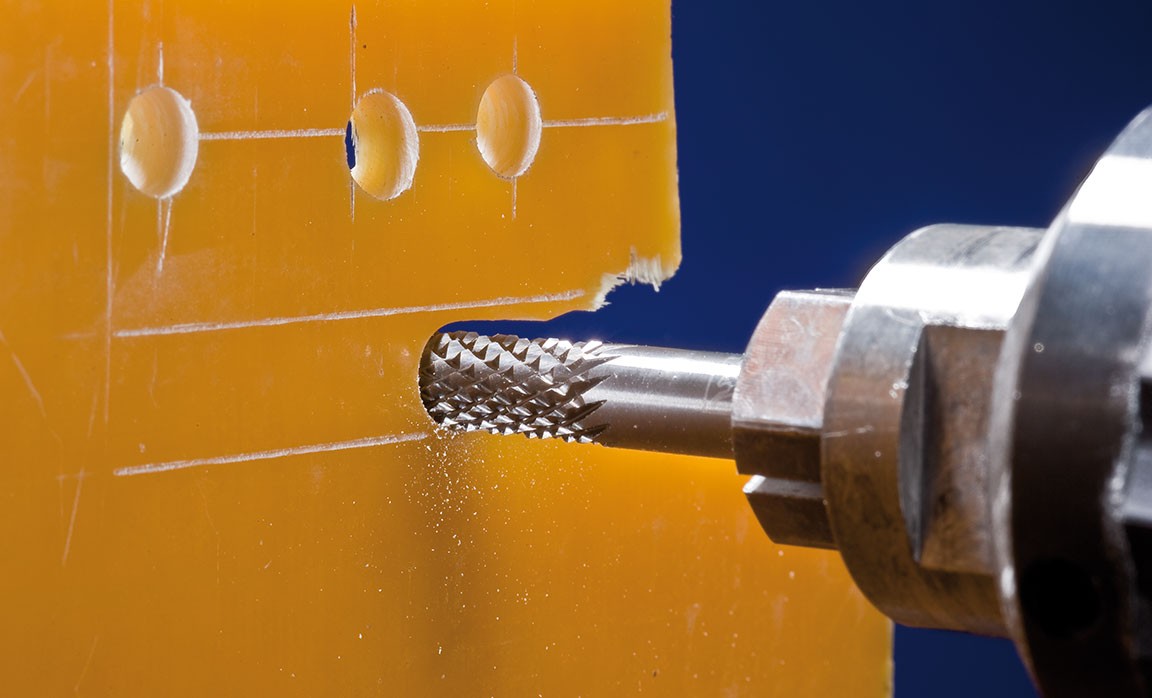

- Plastics

- Fibre-reinforced plastics (GRP/CRP) with a fibre content > 40 %

Applications:

- Trimming

- Contour milling

- Deburring

- Milling grooves and pockets (with FSTS)

- Drilling blind holes (with FSTS)

- Drilling with minimal burr formation (with STS)

- Milling out

- Cutting out holes

Matching tool drives:

- Flexible shaft drive

- Straight grinder

- Robot

- Machine tools

Recommendations for use:

- The version with a drill cut (BS) is particularly suitable for machine and robot applications, while the version with a centre drill (ZBS) is used for manual applications. It allows secure drilling on almost all surface conditions.

- Select a burr diameter greater than the thickness of the material to be machined, to avoid impacts and chattering with the risk of damaging or breaking the tool.

- Increase the rotational speed if the tool tends to chatter.

- If necessary, reduce the rotational speed and contact pressure if melting occurs.

- If possible, use the tools on powerful drives with elastically mounted spindles to avoid vibration.

- For the cost-effective use of burrs, work with higher rotational/cutting speeds.

- Power recommendation for tool drives:

- Shank diameter of 3 mm: 75 to 300 watts

- Shank diameter of 6 mm: from 300 watts

- Please observe the rotational speed recommendations.