Technical information

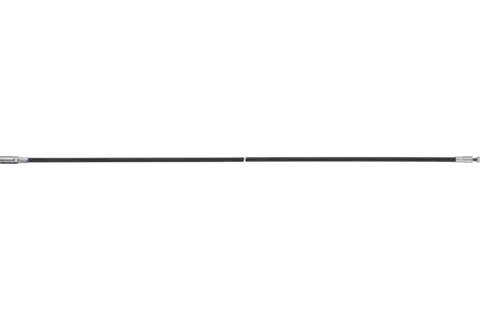

Core SE 7 PST-T DIN 10/M5 2 m

- Dia. drive-side coupling [mm]

- M10

- Dia. external

- 7 mm

- Dia. thread

- M5

- Dia. tool mounting

- 5 mm

- Drive-side coupling, DIN

- 10

- Height

- 7 mm

- Length

- 2031 mm

- Net weight

- 0.447 kg

- PFERD TOOLS type

- SE 7 PST-T DIN 10/M5 2 m

- Rotational speed range

- 1500 - 4250 RPM

- Width

- 7 mm

- Packaging unit

- 1 piece

Description

Recommendations for use

Ordering notes

Safety notes